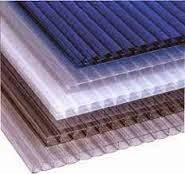

Multiwall polycarbonate panels are

available in spectrum of sizes, thickness and colors. Materialist properties

differ from one variant to another; so, analyze the use before chasing the

latest trend of using

multiwall polycarbonate sheets.

Multiwall Polycarbonate sheets are

giving a new look to modern designs of spaces with enhanced usability. These

have emerged as the cost effective alternative of traditional glazing materials

in variety of spaces including commercial greenhouses, hobby greenhouses, decorative

office partitions, vertical glazing, industrial roofing, pool enclosures, patio

coverings, window replacements, skylights, domes, shelters, canopies, sheds, covered

walkways, carports and sunrooms etc.

Multiwall polycarbonate panels are

available in spectrum of beautiful colors like clear, opal, white and bronze.

Other colors like blue, gray and green are also available on demand. Glazing of

top branded plastic multiwall sheets can be trusted for being of high-quality;

these are made to perform for decades requiring almost no maintenance. Many

brands offer warranty spanned up to 10-years to exhibit their confidence in

produced quality and win the trust of buyer as well. The warranty covers the

issues like excessive yellowing, loss of impact strength because of weathering

and light transmission loss.

Polycarbonate

Lexan multiwall panels are 10 times stronger in comparison to acrylic sheets;

as well these are 200 times strong than glass panels with temperature range

suitability from -40C to 120oC. These are highly flexible and can be

cold formed easily. This property delivers freedom from worries of cracks or

splintering during fabrication.

The experienced benefits of clubbed properties

that contribute in the increasing demand of polycarbonate

multiwall panels are extremely lightweight, highly thermal insulator,

high impact resistant, excellent light transmission, extended structural

durability, weather resistant and UV protection, easy to install, space saving

during storage and fire resistant etc. Ultra stiff polycarbonate sheet with 3

wall x-structure is 10mm - 16mm thick; High Insulation polycarbonate 5 walls

and 9walls sheet come with thickness of 10mm - 16mm and 20mm-25mm. structure

too may be selection criteria for the experienced users; the search may be

focused upon Tunnel, Rectangular and X types.