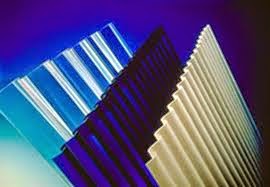

Polycarbonate is a special category of

thermoplastic polymer. It can be easily thermoformed, molded and worked upon. Polycarbonate Profiled sheets

are very durable and are known for having proven impact resistance the most

desired nature in industrial and commercial applications, where life and safety

both matter.

The

properties that make Lexan Polycarbonate Profiled sheets the ultimate choice for diverse applications

include rigidity, toughness, heat resistance, elasticity, chemical resistance, abrasion

resistance and electrical insulation etc. Polycarbonate Corrugated sheets are virtually unbreakable, light

weight, easy to install, easy to clean and weather resistant. These can

be rolled up easily for easy handling and can be cold-formed to form the

curves. Quality Polycarbonate Lexan corrugated sheets keep the harmful UV rays

out of usage area with no compromise with light. Lexan Polycarbonate sheets of

about .033 mm thickness, can withstand up to 230-250 inch

pounds pressure within temperature range of -40F to 250F. Lexan Corrugated sheets insulate the spaces with 1.2 U value; it

means you save on account of water consumption, air-conditioning etc. Polycarbonate Profiled sheets are unharmed by chemical substances; still, these should be

avoided from long time direct contact with paints, solvents and adhesives.

Chemicals that you should avoid include benzene, acetone, carbon-tetrachloride

and gasoline etc.

The materialistic and

applicable characteristics of Lexan profiled sheets make them perfect choice of

common and innovative applications. Noncorrosive Polycarbonate Corrugated sheets having wide temperature

resistance capability find

the applications in architectural roofing, skylights, industrial roof lights, agricultural

greenhouses, residential pergolas, canopies, awnings and light roofing etc. The

major fields inviting innovative uses of polycarbonate profiled sheets are

agriculture, construction, architecture, display, signage, DIY, aesthetic

fabrication etc.

The promising properties of Polycarbonate

Corrugated sheets depend upon the quality of manufacturing standards;

even the slight change in combination of

raw materials may change the properties much. So, buy the Lexan Corrugated

sheets only through genuine channel partners of leading brands.